What are roll plate bending machines used for?

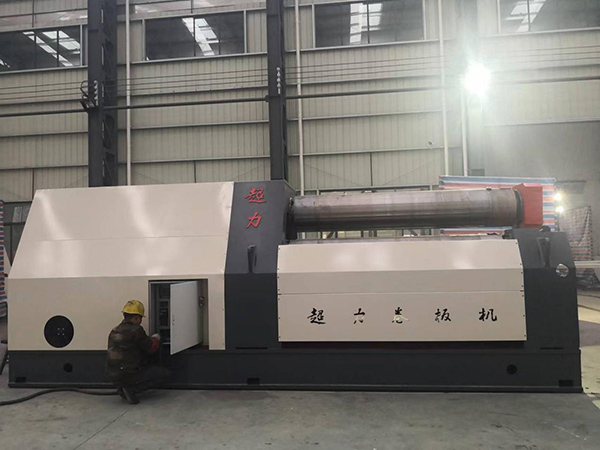

A roll plate bending machine is designed to bend and shape metal plates into the desired form. It's versatile enough to handle various types and thicknesses of metal, making it ideal for creating pipes, containers, barrels, ships, and other industrial products.

What types and thicknesses of metal can the roll plate bending machine handle?

The roll plate bender works with a range of metal materials including aluminum, steel, stainless steel, carbon steel, and manganese steel plates. It's capable of bending metal plates of various thicknesses, showcasing its adaptability and flexibility.

How difficult is it to operate a roll plate bending machine?

Operating a roll plate bending machine is relatively easy after basic training. It features an control interface that allows for quick adjustments and bending processes.

What is the production capacity of a roll plate bending machine?

Its capacity to process metal plates efficiently depends on the material, thickness, size, and the desired bending angle. Typically, roll plate benders can handle multiple metal plates per hour.

Does the roll plate bending machine have energy-saving or eco-friendly features?

Yes, the machine is designed with advanced technology, including a high-speed ratio K series reducer paired with a low-power motor, which achieves high torque while being energy-efficient and eco-friendly.

What bending shapes can the roll plate bending machine support?

It can perform a variety of bending shapes, including symmetrical, asymmetrical, and circular arc bending, customized to meet specific requirements.

What control system does the roll plate bending machine use?

Our roll plate bending machines use an advanced CNC system with Siemens PLC and touchscreen for free programming of rolling, plus it includes roller position monitoring and automatic leveling systems for precise bending control.

Does the roll plate bending machine have safety features or emergency stop functions?

Yes, the machine includes multiple safety measures like emergency stop buttons and overload protection to ensure operator safety during use.

Can the roll plate bending machine handle large metal plates?

Absolutely, the machine is designed with flexibility in mind, capable of processing large-size metal plates while maintaining stable bending results.

Does the roll plate bending machine offer customized solutions?

Yes, we offer customized Roll Plate Bending Machines, including wider/longer models and special shape bending options, tailored to meet unique manufacturing needs.

In which industries is the roll plate bending machine widely used?

It’s widely used in various applications such as in shipbuilding, pressure vessel manufacturing, silo making, petrochemicals, bridge engineering, and metal structure manufacturing, fulfilling diverse bending processing needs.

What is the main purpose of a shearing machine?

A shearing machine is used for cutting metal plates, offering a quick and precise way to trim metal materials.

How does a shearing machine work?

It operates using a hydraulic system, employing movable upper and fixed lower blades to precisely shear metal plates through pressure and cutting force.

What types and thicknesses of metal can the shearing machine handle?

It's designed for shearing various metal types, like steel and stainless steel plates, capable of dealing with thicknesses typically ranging from 1mm to 20mm.

What is the shearing capacity and scope of a shearing machine?

The shearing machine can handle metal plates of different thicknesses and lengths, featuring strong shearing capabilities and adaptability.

How difficult is it to operate a shearing machine?

Shearing machines are user-friendly, equipped with an intuitive control panel that allows operators to quickly learn and perform cutting tasks after basic training.

What are the main features of a hydraulic press brake?

Hydraulic press brakes use a hydraulic system for precise metal bending, offering high automation and accurate bending capabilities.

Does the hydraulic press brake come with an automated control system?

Yes, it typically features an advanced CNC system for precise control over bending angles and pressure, enhancing operational efficiency and accuracy.

What role does the welding center play in metalworking?

The welding center serves as an integrated system for various welding processes, enabling efficient and precise metal welding.

What welding processes does the welding center offer?

It supports multiple welding processes, including TIG, MIG/MAG, PAW, SAW, etc., catering to different welding requirements with light, standard, and heavy-duty models available in fixed, rotating, and mobile configurations.

How do conventional and self-alignment welding rotators differ?

Conventional Welding Rotators usually require manual adjustment of the workpiece, whereas Self-alignment Welding Rotators automatically adjust to the center of the workpiece for more convenience and precision.

Where are welding rotators typically used?

They're widely used across various sectors including wind power, pressure vessels, petrochemicals, pipelines, steel constructions, boilers, shipbuilding, and overlay welding repairs. Customizations like electric trolleys, retractable arms, personnel platforms, and maintenance ladders, as well as various tracking and monitoring, arc swinging, and flux recovery systems, can be added to meet specific user requirements.

What type of control system does the welding center use?

The Welding Center utilizes a digital control system for convenient and precise operation, facilitating easy integration with other devices for coordinated control.

What maintenance is required for these products?

Maintenance involves lubrication, cleaning of key components, tool upkeep (such as for shearing machines and press brakes), inspections and cleaning of welding equipment (welding center and welding rotators), regular checks and calibrations of components, recording maintenance data, and establishing a maintenance schedule, ultimately adhering to manufacturer recommendations and regular professional servicing to ensure stable operation and extended service life.

Are there any successful cooperation stories or customer feedback available for reference?

Yes, we have a wealth of success stories and positive customer feedback that showcase the widespread application and approval of our machines across various industries.

What kind of after-sales service support is offered?

We provide comprehensive after-sales service support, including remote technical support, maintenance services, and necessary part replacements. We're committed to ensuring smooth operation and ongoing support for our customers throughout their use of our equipment.