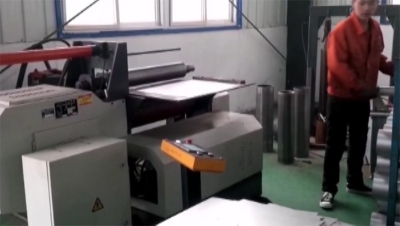

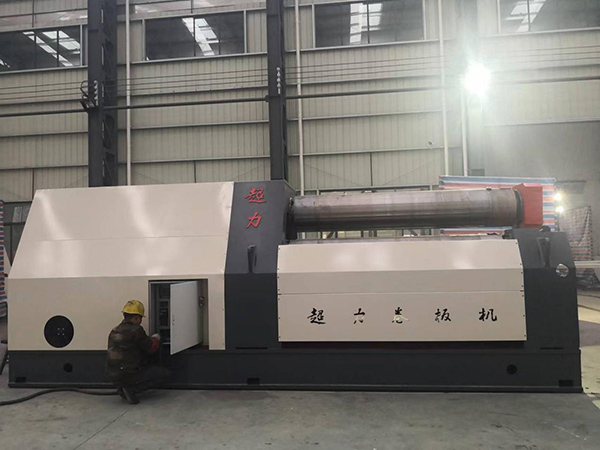

2-Roll Plate Bending Machine

As a new type of rolling machines, 2 roll plate bending machine is equipped with 2 rollers, one is made from steel and the other one is comprised of a steel core covered by an elastic layer (rubber roll). The plate is arranged between the 2 rolls with an adjustable distance. With the processes of contacting - pressing - rubber roll deforming, the plate is deformed partially thus driving both the 2 rolls to rotate. Then a continuous rolling and forming process will be realized. This roll bending machine is of high production efficiency and lightweight structure, and is able to form the plates into one piece. The plates it processes are highly valued for high geometric accuracy and smooth plate surface. The adoption of PLC (programmable logic controller) for the sheet metal bending equipment allows for an easy operation and numerical control.