Profile Bending Machine

Profile Bending Machine

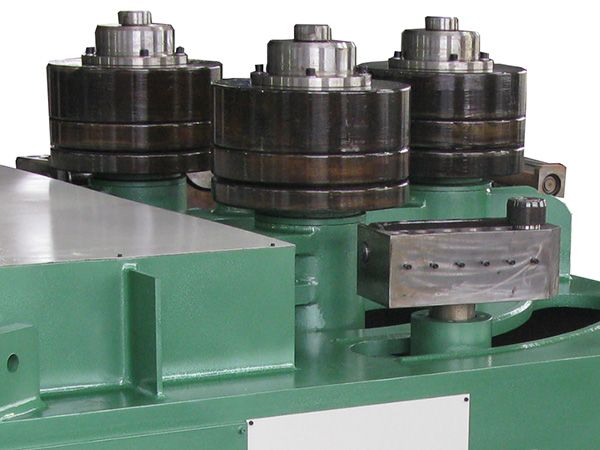

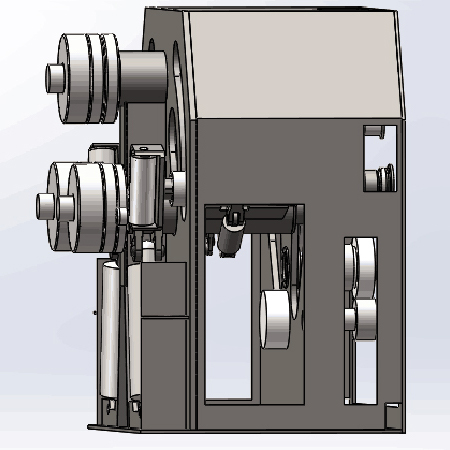

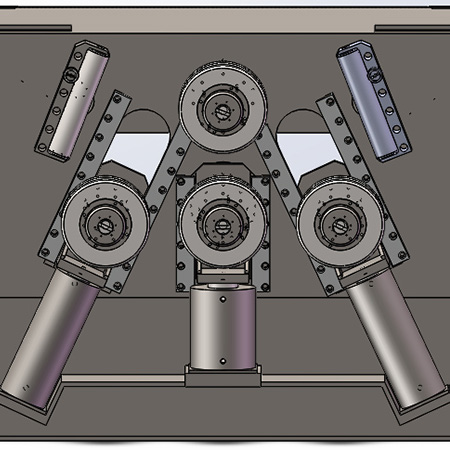

The profile bending machines we offer at Chaoli, are engineered for versatility, capable of performing precise pre-bending on various profiles. They consist of the main body, side roller parts, support rollers, transmission components, electrical system, hydraulic system, and molds, all designed for optimal performance.

- Equipped with three roller shafts acting as main driving rollers, our metal processing machines can handle small diameter profiles without slipping, broadening their applicability.

- The bending molds are made from 42CrMo alloy steel, subjected to tempering (HB240~280) and surface quenching. This ensures excellent mechanical properties, high strength, wear resistance, and longevity, even under high-load conditions.

- The rotation of the three roller shafts minimizes power loss through rolling friction. Bearings designed for low speed, high load, and high torque contribute to the profile bending equipment’s high work efficiency and significantly lower power consumption.

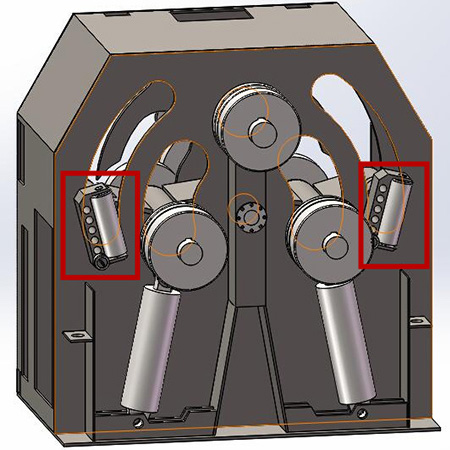

- Innovative side roller adjustment:

Our design replaces traditional slide paths with swing arms, eliminating the common issues of wear and high friction found in conventional designs. This innovative approach reduces wear parts and extends the machine’s lifespan.

The side rollers are adjusted through a combination of swinging arms and hydraulic cylinders, employing the principle of leverage to minimize energy loss. This efficient system ensures smooth and precise adjustments, enhancing the machine’s versatility and performance. - The profile bender includes a movable control station equipped with switches, buttons, and a display screen showing the positions of the side rollers, making operations intuitive and convenient for the operator.

- Our profile bending machines are equipped with Siemens electrical components, known for their long service life and reliability. Our electrical system includes safety features like overcurrent, overheating, overload protection, and safety interlocks for hydraulic actions, ensuring safe operation.

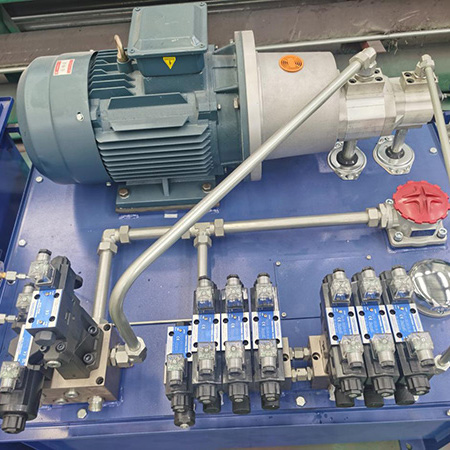

- Our hydraulic system uses high-quality valves from Yuci-Yuken, featuring cast flow channels for high flow rates, low resistance, low-pressure loss, and minimal heat generation, enhancing machine reliability. We use advanced, quick-connect fittings designed for the demanding conditions of the mining and metallurgy industries, featuring reliable radial seals that prevent hydraulic oil leaks during operation. The hydraulic system is equipped with both suction and return oil filters to maintain the system's cleanliness and an air filter to ensure the oil tank can properly breathe and moisture can evaporate. With dual safety mechanisms in place, the system guarantees the safe use of the equipment under all conditions.

- The profile bender’s frame and base have a stress-relieved welded structure to eliminate internal stresses and enhance bending accuracy. Its strong integral base makes lifting and installation straightforward.

| W24S- Profile Bending Machine Technical Parameters | |||||||||||||

| Model | 6 | 16 | 30 | 45 | 75 | 100 | 140 | 180 | 260 | 320 | 400 | 500 | |

| Max elastic section modulus (cm3) | 6 | 16 | 30 | 45 | 75 | 100 | 140 | 180 | 260 | 320 | 400 | 500 | |

| Rolling speed (m/min) | 6 | 6 | 6 | 6 | 5 | 5 | 5 | 4 | 4 | 4 | 4 | 4 | |

| Profile Yield Strength (Mpa) | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | |

| Max section of angle bending | 40×5 | 70×8 | 80×8 | 90×10 | 100×10 | 120×12 | 140×16 | 150×16 | 160×16 | 180×14 | 200×18 | 200×20 |

| Min bending diameter | 800 | 1000 | 1200 | 1500 | 2000 | 2400 | 2500 | 2600 | 2600 | 3600 | 3600 | 4000 | |

| Max section of angle bending | 50×5 | 80×8 | 90×10 | 100×10 | 120×12 | 140×16 | 150×16 | 160×16 | 180×14 | 200×18 | 200×24 | 250×25 |

| Min bending diameter | 800 | 1000 | 1100 | 1300 | 1600 | 1800 | 2200 | 2000 | 2500 | 3600 | 3600 | 4000 | |

| Max section of C-channel bending | 8# | 12# | 16# | 20# | 25# | 28# | 30# | 32# | 36# | 40# | 45# | 50# |

| Min bending dia. | 600 | 800 | 800 | 1000 | 1100 | 1700 | 1200 | 1500 | 1800 | 2000 | 2000 | 2400 | |

| Max section of C-channel bending | 8# | 12# | 16# | 20# | 25# | 28# | 30# | 32# | 36# | 40# | 45# | 50# |

| Min bending dia. | 700 | 900 | 1000 | 1150 | 1600 | 1700 | 1700 | 1800 | 1800 | 2000 | 2000 | 2000 | |

| Max section of bending flat bar | 100×18 | 150×25 | 180×25 | 200×30 | 220×40 | 250×40 | 280×50 | 300×50 | 330×50 | 360×60 | 400×75 | 500×76 |

| Min bending diameter | 600 | 700 | 800 | 900 | 1000 | 1200 | 1300 | 1500 | 1900 | 2000 | 2400 | 2400 | |

| Max section of bending flat bar | 50×12 | 75×16 | 90×20 | 100×25 | 110×40 | 120×40 | 150×40 | 180×30 | 190×40 | 190×50 | 200×50 | 200×60 |

| Min bending diameter | 500 | 760 | 800 | 1000 | 1100 | 1300 | 1500 | 2000 | 2000 | 2400 | 2200 | 2500 | |

| Max section of bending pipe | 42×4 | 76×4.5 | 89×5 | 89×8 | 114×5 | 159×5 | 168×6 | 168×8 | 219×8 | 245×8 | 273×8 | 323×10 |

| Min bending diameter | 500 | 750 | 900 | 900 | 1200 | 2000 | 2000 | 2000 | 3500 | 3000 | 3500 | 4200 | |

| Max section of bending round steel | 38 | 52 | 62 | 75 | 85 | 90 | 100 | 110 | 120 | 135 | 150 | 160 |

| Min bending diameter | 450 | 600 | 600 | 800 | 1000 | 1100 | 1200 | 1300 | 1350 | 1800 | 2000 | 2000 | |

| Max section of bending square | 45×3 | 60×4 | 70×4 | 80×6 | 90×8 | 100×10 | 125×10 | 140×10 | 150×10 | 165×10 | 180×12 | 200×12 |

| Min bending diameter | 750 | 900 | 1000 | 1200 | 1600 | 2000 | 2500 | 3000 | 3000 | 3500 | 3500 | 5000 | |

| Max. section | / | / | / | / | 10# | 12.6# | 14# | 16# | 18# | 20.6# | 22.6# | 25.6# |

| Min. bending diameter | / | / | / | / | 2000 | 2500 | 3000 | 3500 | 4000 | 5000 | 8000 | 10000 | |